Inventory Management Statistics Worth Knowing

These inventory management statistics will help you optimise your inventory in the best ways possible, so we can promise that they are completely worth knowing.

But hey! Don’t take our word for it. Keep reading and learn everything that there is to learn about inventory management statistics.

Content

- Inventory Management Statistics – Problems

- Inventory Management Statistics – Technology

- Conclusion

Inventory Management Statistics - Problems

First of all, let’s have a look at inventory management statistics that can help us understand the problems businesses generally face when it comes to managing their inventories and handling the stock.

You can achieve 10% lower inventory costs by simply reducing the problems of overstocking and under stocking. (Zebra)

Overstocking and under stocking are two very common problems that occur within your inventory. As the name suggests, overstocking refers to when you have more stock at hand in comparison to customer demand, whereas under stocking happens when you have less than required. Either situation are harmful, and as depicted by this particular statistic, you can fix your inventory and cut back on costs by simply just eradicating two of these problems.

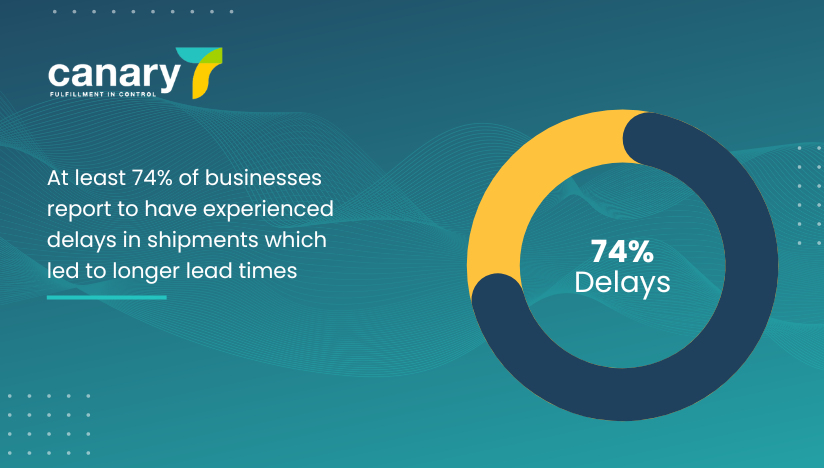

At least 74% of businesses report to have experienced delays in shipments which led to longer lead times. (Capgemini)

It is important to understand that inventory management is inextricably linked to how you perform as a business. If your inventory reaches you late, it will also leave your warehouse late, which will make the whole process late and not up to the mark. Needless to say, this is not feasible when you are trying to improve your customer satisfaction levels, and can cost you in both time, money, and customers.

The USA itself has experienced 298 weather and climate disaster events since 1980, the cost of which has exceeded $1.975 trillion. (NCEI)

Sometimes, the reason why it becomes hard to take care of your inventory is that it is vulnerable to things beyond your control. This stat gives us insight into the USA which is prone to many natural and weather-related disasters. These disasters cause a disruption in the supply chain, and can therefore have an impact on your inventory health. Due to this, inventory management is a process that requires a certain level of preparation done in accordance with the prospect of having to deal with natural disasters. This is neither cheap or convenient in most cases, but must be done if you don’t want your business to face any major detriment.

Across all industries, 74% have reportedly experienced a shortage of critical parts and materials across all industries. (McKinsey and Co)

Again, inventory management problems don’t always mean that there is something wrong with what you are doing. Sometimes, external factors like shortages also play a part in deciding the trajectory of your inventory management processes. And this is something that, as shown by this particular stat, is not pertinent to one industry or the other. It applies to all industries, and hence every business out there must know how hard it is to stock up on the right critical parts and materials to maintain the optimal inventory levels.

The projected increase in the cost of shipping raw materials is 50%, due to global efforts made by countries to rebuild their inventories after the pandemic. (Bloomberg)

The pandemic left many economies all over the world struggling. Of course, the rebuilding of these post-pandemic involved recreating many business processes from scratch, including the inventories. This means that there has been a larger demand for inventory supplies, which has made it even harder to get your hands on them for most people. As the stat suggests, another problem this has caused is an increase in the cost of inventory shipping. Now, because inventory management is generally known to tip on the more expensive side, it becomes apparent that increased shipping cost is problematic and more likely to cause problems.

There has been at least a 30% increase in shipping costs due to the shipping container shortage and the subsequent increase in split shipping. (Establish)

Another factor that has caused an increase in shipping costs is the container shortage issue. Essentially, the world is running short on containers in which things can be shipped in. This has led to split shipping, which means breaking down consignments and shipping them separately, in whatever container they get space in. Needless to say, it has also resulted in a spike in shipping costs, and is therefore yet another concerning element for businesses to keep in mind. This stat is important to keep in mind if you are a business struggling with their cash flow.

34% businesses have shipped an order late due to having sold a product that was not actually in stock. (Meteor Space)

Many businesses feel they can get the right insights into their inventories. This means that they don’t have a clear idea on what their inventory levels are like. In addition, these businesses don’t have the required integration between their sales channels and their inventory management processes, which means that it is quite common for them to sell products they don’t even have in stock. As you probably know, this can be quite embarrassing for a business to go through and hence, should be avoided at all costs if you don’t want to leave a lasting negative impact on your customers in the future.

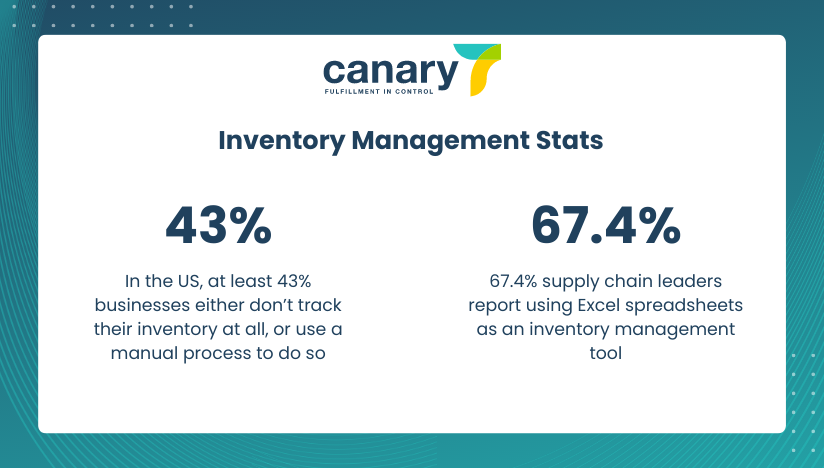

In the US, at least 43% businesses either don’t track their inventory at all, or use a manual process to do so. (Waspbarcode)

Despite inventory management being a critical part of a businesses’ success, not a lot of businesses actually make an effort when it comes to tracking it. If you don’t track your inventory at all or do so using inefficient, manual processes, then you are lagging behind your competitors with better methods of inventory management – which is obviously a huge disadvantage. While the problems associated with not tracking your inventory are apparent, using manual processes that are simply not advanced enough to help you get the best look at the state of your stock are also not enough in that regard.

67.4% supply chain leaders report using Excel spreadsheets as an inventory management tool. (Zippia)

That is concerning! Although Excel is a pretty good spreadsheet software, it is simply not advanced enough to help a business with inventory management. In fact, any software that requires manual processing of inventory data is not good enough. This is because in order to maintain optimal inventory levels, you need an inventory management software that updates in real-time and automatically updates information. This is the only way you can have an accurate view of your inventory activity, and it is also the way you get to make sure that your inventory health is up to the mark.

U.S retail operations only have an accuracy of 63% on an average. (Zippia)

While that might seem like a high number, it really isn’t! In order for you to be successful in the area of inventory management, you need to have at least 98% accuracy. This decreases your chances of miscalculating things during the order fulfillment and also helps you cut back on errors. However, it can be seen from this particular stat that businesses are struggling with this element and there really isn’t a lot you can actually do in this regard other than transforming the way you manage your inventory and make it more advanced and data-friendly from the very scratch.

21.6% businesses are unsure which inventory management direction they are going to choose. (Compunnel Digital)

Inventory management is best done in tangent with proper planning and execution. That fact that a relatively bigger chunk of businesses are unsure on how to execute their inventory management processes and as well as what direction they are going in shows that this is another element that businesses are likely to struggle with. This is problematic because if they are unsure at these points, that means they lack a proper plan and their inventory management methods are likely to be disorganised and all over the place, which will most definitely do more harm than good in every single regard.

23% businesses lack visibility across the supply chain, including the area of inventory management (Compunnel Digital)

If you don’t have visibility into your inventory management framework, you are likely to make mistakes and decisions that don’t really fit in with the goals of your business. The fact that 23% businesses lack visibility is actually quite concerning, since visibility is one of the most integral components of inventory management. It is likely that this lack of visibility stems from a reliance on ineffective inventory management methods, including but not limited to manual processes that are simply not advanced enough to help you successfully meet the ever evolving and high maintenance needs of customers in the 21st century.

Inventory Management Statistics - Technology

If the aforementioned inventory management statistics on inventory management problems dampened your spirits, then here’s some good news to cheer you up: almost all those problems can easily be fixed if you integrate the right technology into your processes.

Don’t believe us? Have a look at the inventory management statistics below:

72% of retailers plan to improve their supply chain with real-time visibility by integrating analytics, sensors, and automation in their processes. (Zebra)

This is great! This stat shows that retailers know exactly what to do in terms of improving their supply chain and have already turned towards technology like automation, sensors, and analytics to enhance their supply chain processes. Using advanced technology to improve your inventory is genuinely the only way you can make a tangible difference to the way you manage your stock, so this particular stat is a breath of fresh air for all businesses.

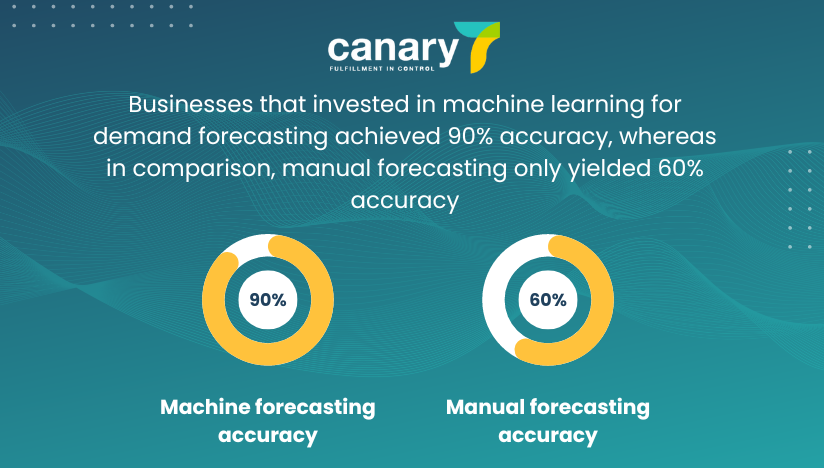

Businesses that invested in machine learning for demand forecasting achieved 90% accuracy, whereas in comparison, manual forecasting only yielded 60% accuracy. (McKinsey and Co.)

In order to achieve the perfect inventory levels, you need to execute accurate demand forecasting. Accurate demand forecasting can be achieved with the help of machine learning. As seen in this stat, if you employ machine learning, you are likely to have better demand forecasting as compared to if you try to do it manually without the right technology and tools. This is why it becomes important for businesses to invest in machine learning as well as other advanced technology as it will only help them improve the way they deal with their inventory.

AI can enhance supply chain and inventory management by reducing logistics costs by 15% and improving inventory and service levels by 35% and 65% respectively, as compared to other competitors. (McKinsey and Co. )

Bringing AI into the centre of your inventory management processes is the best thing you can do for your business. As it can be seen from the stats, using AI can help you in many regards. For example, it can reduce logistics costs and help you optimise your finances better. Not only that, it can also help you maintain the right inventory levels and improve your services as a whole to a great extent, which is definitely one of the best ways to make sure that your inventory management efforts ultimately align with the preferences of your customers.

According to 70% of retail and manufacturing businesses, they have already started working on a digital transformation of their project in supply chain operations. (Business Insider)

Again, this is indicative of the fact that businesses realise what they need to do in order to make inventory management a better experience for them, and it is digital transformation. The sooner you join this trend, the better it will be for you! This is because if you get a head start on evolving your inventory management methodologies, you can easily leave your competitors biting the dust and emerge as an unmitigated industry leader in this particular area of your business development.

According to 92% manufacturing executives, production planning, which is an important aspect of inventory management, can be greatly improved by the help of AI And cognitive computing. (IBM)

92% manufacturing executives means almost ALL manufacturing executives out of those surveyed are of the view that production planning can be improved through artificial intelligence. And that is true! AI can help you make the right choices when it comes to production planning, which means that as you move ahead, these choices can also be reflected in the way you execute other inventory management processes. AI can help you make the whole journey more holistic and well-put, which means you don’t have to worry about things lagging behind and hence, even gain a competitive advantage over your competitors present in the industry.

The Internet of Things is the fastest growing industry and is predicted to reach a $1.1 trillion mark in 2022. (Exploding Topics)

The term internet of things or IoT refers to a system of interrelated computing devices. It can be a part of various verticals, such as automotive, telecom, energy segments. The most simple to understand example of an IoT set up is a smart home that is filled to the brim with interconnected devices like smart appliances and electronic devices that can be controlled with smartphones. It is the fastest growing market, which means that we will see a greater presence of it in the world of inventory management as well. And this is for the best, as it can help us improve our inventory management set up in all the perfect ways.

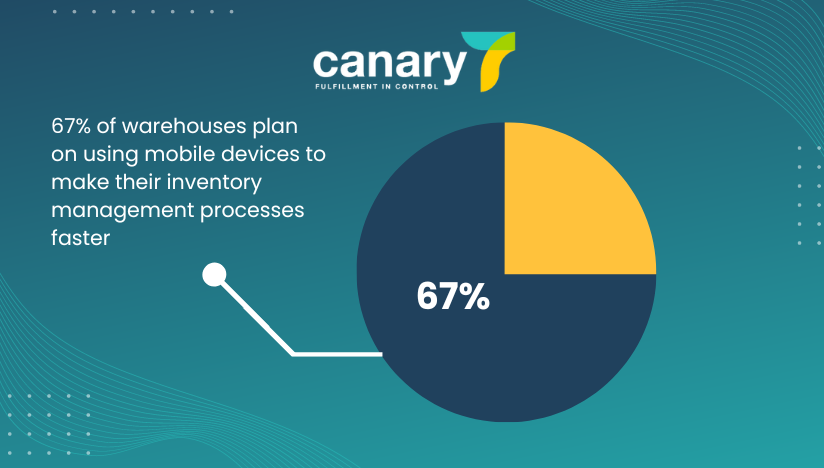

67% of warehouses plan on using mobile devices to make their inventory management processes faster. (Capterra)

Way over half of warehouses are already ready to use mobile devices to make their inventory management processes better. This tells us that something as small and relatively simply as mobile devices can make your inventory 10 times better. The main advantage it provides is efficiency, which means that all businesses that are planning on speeding up their inventory management processes need to focus on leveraging mobile technology, as it can help you achieve your goals much faster! Needless to say, the greater level of efficiency you achieve with your inventory processes, the faster your deliveries are, the more sales you can make, and of course, the more customers you can win over!

25% more retailers are investing in new warehouse management systems because they are a must today. (Upkeep)

25% more retailers believe that warehouse management systems are critical than in the past. This suggests a change in attitude towards using technology in the warehouse, and most of it can be attributed to the fact that warehouse management systems as well as other kinds of technology can actually make an impact on your fulfilment strategy and help you achieve your desired results much, much faster and in a much better way. These businesses have realised this, and its time you do too.

According to 81% of businesses, analytics can help reduce supply chain costs. (Michigan Tech)

Reducing your supply chain costs can be as simple as employing analytics. Analytics will help you not only produce but also make sense of accurate data. You can then base all the important business-related decisions on data findings. This will help you avoid a lot of loss and detriment, and ultimately makes it easier for you to cut back on the unnecessary costs that would otherwise add up to your spending and make it worse for you especially if you are working on saving more money in inventory management as a business.

79% high-performing supply chains are reported to achieve better revenue growth than the average in their industry. (Michigan Tech )

This means that an advanced inventory management process can help you achieve better revenue growth than your competitors. What this should mean essentially is that if there is one thing you really need to focus on, at least as far as the back end processes of your business are concerned, is your supply chain and inventory. This is because even slight adjustments in the way you do things here can help you make it a more contributive factor for your overall success as a business, and hence should be on the top in your list of priorities.

Businesses with optimised supply chains have about 15% lower supply chain costs than businesses who don’t. (Michigan Tech)

Inventory management and your spending is really closely linked. After all, holding costs for your inventory can really be a lot, and it is generally with inventory and stock that businesses have to spend the most. Due to this, it is natural that many businesses want to try and get their costs down. This stat is an authority on the fact that optimising your supply chain can actually lead to 15% lower supply chain costs, which means you can save money on that end without any major considerations. Although “optimising” the supply chain may mean different things for different businesses, integrating the right technology in your processes is a great way to start in this area.

Businesses with optimal supply chains have 3 times faster cash-to-cash cycles. (Invesp)

If having a better cash flow is one of your biggest priorities, you might want to have a look at the way your supply chain and inventory operates. You may identify certain lags in these particular segments, and fixing these lags can help you improve your cash flow to a very great extent. This stat shows that optimal supply chains can have better cash-to-cash cycles, so if that’s what you want then you need to start thinking about enhancing your supply chain right away – preferably with the right kind of technology.

It is reported that item-level tagging, when applied effectively, can increase inventory accuracy from 63% to 95%. (PR Newswire)

Item-level tagging, which can be achieved with the help of the right technology can really help businesses make a difference when it comes to their inventory health. According to this stat, if you are looking to increase your inventory accuracy and that too in a rather prominent way, you need to turn to methodologies like item-level tagging that can easily be executed with the help of technology! Obviously, this can only be done when this technology is applied and implemented properly, but that is no rocket science and we are certain that any businesses, with the right level of effort, can achieve great success in this regard.

About 42% of warehouses and distribution centres are projected to make investments in technology and automation. (Logistics Management)

Almost half of the documented warehouses are ready to make investments in technology and automation. If you were sceptical about whether it’s worth it or not, the fact that 42% of warehouses are ready to do it should be an affirmation for you. The thing is, the sooner you start working on solidifying your inventory management procedures, the easier it is for you to start cashing in on the benefits provided by these additions to your fulfilment strategy, and better you can develop and expand your business!

According to a study, human error was reduced by 43.5% via the utilisation of barcode technology on medication at an academic medical centre. (Source: National Center for Biotechnology Information)

Human error is one of the most common things that can happen in the warehouse. However, when it comes to your inventory, you can’t afford much human error as it can cause serious detriment to your profits. Yet, if you rely on manual systems, human error is bound to occur. As this statistic proves, it can be avoided to a great extent with the utilisation of the right automation and technology. Less human errors mean less time, effort, and resources spent on rectifying them and a generally better inventory management strategy to rely on for the best results.

The demand for inventory management software market is expected to rise at a CAGR of nearly 11.2% during the forecast period 2022-2028.

The demand for inventory management software, as seen here, is only expected to increase in upcoming years. This means a couple of things. Firstly, this could signify the need for better inventory management processes and therefore added pressure on businesses to provide that. Secondly, it also means that the inventory management industry is going to advance forward and become even better. Either way, it is a sign for businesses to start looking into finding the right inventory management software for themselves – today!

The inventory management software market is expected to reach the value of USD 3.82 billion and grow at a CAGR of 6.12% from 2021 to 2028 (Databridge)

Because the demand for inventory management software is growing, so is the inventory management software market. Although this is good in terms of the variety of inventory management solutions available to make use of, it could also present a challenge in terms of identifying which inventory management solution goes the best with you. You obviously have to keep in mind the affordability factor, but that’s not all. It is also important to make sure that the inventory management software actually connects with the goals that you have in mind for your business. There will be many systems available in the market, but only some of them can become a good addition to your business – and it is up to you to find the perfect one.

There are currently 75 software vendors offering inventory management solutions. (Software Path)

This number will only increase in the future – which again means that you have a lot of options you can choose from. Don’t be overwhelmed by the range of selection available. Do your research and take your time in finding an inventory management system that you can actually commit to. If you can, try out the inventory management solution before you make the choice of committing to it for good. For example, Canary7 offers a free demo that you can take before you actually sign up with us – simply because we want you to truly make a choice that is the best for you.

Final Notes

Inventory management is the kind of area of your supply chain that is simply bound to present many challenges. However, you can prepare yourself for these challenges and navigate them with extreme professionalism with an inventory management system as well as other inventory and stock handling technology.

The best news is that your search for the perfect inventory management software ends now, because Canary7 is all that you need in terms of handling your stock.

Colleen Ballantine

Author

UPDATED ON: 20th Dec 2022

Colleen is a marketing specialist at Canary7, writing in-depth blog content on warehouse management, inventory control, and logistics. With extensive industry experience, Colleen focuses on delivering informative and insightful posts

Subscribe to get latest posts straight in your inbox.